Sterilization plays a crucial role in preventing infections in healthcare settings, ensuring that medical instruments and devices are free from harmful microorganisms. However, how can healthcare professionals be sure that sterilization processes are effective? This is where Chemical Indicators in Sterilization (CIs) come into play.

What Are Chemical Indicators?

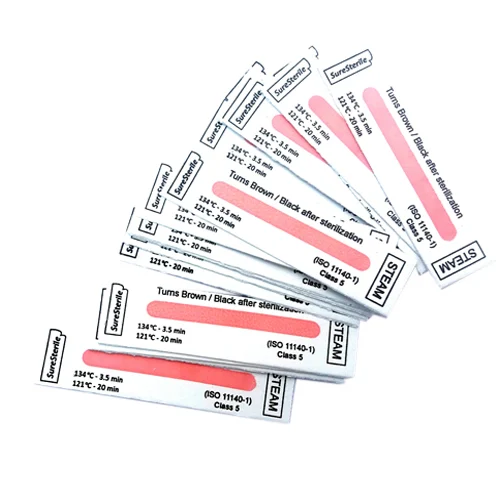

Chemical indicators are designed to visually confirm that specific conditions required for sterilization have been met. They change colour or display a response when exposed to the sterilizing agent—whether it’s steam, ethylene oxide (EtO), or plasma. These indicators provide immediate feedback and help verify that the sterilization process is functioning correctly.

Types of Chemical Indicators Based on Sterilization Methods

1. Steam Sterilization (Autoclave) and Chemical Indicators

Steam sterilization is one of the most widely used methods due to its reliability and efficiency. It uses high-pressure saturated steam to eliminate pathogens.

How Chemical Indicators Work:

CIs for steam sterilization contain heat-sensitive chemicals that change colour when exposed to proper sterilization conditions (time, temperature, and steam saturation).

Limitations:

Chemical indicators alone do not confirm sterility; they indicate exposure to steam conditions but not the complete elimination of all microbes.

2. Ethylene Oxide (EtO) Sterilization and Chemical Indicators

Ethylene oxide is used for heat- and moisture-sensitive instruments, such as catheters and endoscopes. This gas effectively destroys microorganisms but requires proper exposure conditions.

How Chemical Indicators Work:

CIs for EtO sterilization react to exposure time, gas concentration, humidity, and temperature.

They often appear as strip indicators or integrators that shift colour once optimal conditions are met.

Limitations:

Chemical indicators do not confirm whether toxic EtO residues have been properly aerated from the instruments, which is crucial to ensure patient safety.

3. Plasma Sterilization (Hydrogen Peroxide) and Chemical Indicators

Plasma sterilization is an advanced, low-temperature method suitable for delicate instruments such as robotic surgical tools and fibre optics. It uses hydrogen peroxide vapour to destroy microbes.

How Chemical Indicators Work:

These indicators change colour when exposed to the correct hydrogen peroxide concentration, time, and temperature.

Plasma-specific indicators include self-adhesive chemical indicator strips that respond to sterilization parameters.

Why Are Chemical Indicators Essential in Sterilization?

- Immediate Verification – Unlike biological indicators (which require incubation), chemical indicators provide instant results, allowing rapid decision-making.

- Ensures Compliance – Regulatory bodies like the CDC, WHO, and ISO 11140 mandate the use of chemical indicators in sterilization processes.

- Prevents Infection Risks – By identifying failed sterilization cycles early, chemical indicators reduce the chances of HAIs, protecting both patients and healthcare workers.

- Enhances Efficiency – Healthcare facilities save time and resources by using multi-parameter chemical indicators, which assess more than one sterilization factor.

Best Practices for Using Chemical Indicators

- Use indicators inside and outside each sterilization pack to verify internal and external exposure.

- Follow manufacturer guidelines for proper placement to ensure accurate readings.

- Monitor and document results regularly to track sterilization process effectiveness.

- Combine with biological indicators where necessary for comprehensive validation.

Conclusion

In modern healthcare, sterilisation is non-negotiable. Chemical indicators serve as the first line of defence in verifying sterilization effectiveness, ensuring medical instruments are safe for patient use. Whether for steam, EtO, or plasma sterilization, the right chemical indicators provide critical assurance that sterilization processes are performing as intended, helping to minimize infection risks and enhance patient safety.

Miracle Industries: Ensuring Sterilization Compliance

Miracle Industries is committed to providing high-quality sterilization solutions. As a trusted supplier of CSDCO-approved chemical indicators, we ensure compliance with global sterilization standards. As the only Terragene Distributor in India, Miracle Industries is dedicated to delivering advanced products to healthcare facilities, pharmaceutical companies, and more across the nation. Choose Miracle Industries for reliable, high-performance sterilization monitoring solutions.

Frequently Asked Questions (FAQs)

1. How do chemical indicators differ from biological indicators?

Chemical indicators provide instant visual confirmation that sterilization conditions have been met, while biological indicators contain live spores and require incubation to confirm sterilization efficacy.

2. Can chemical indicators alone guarantee sterilization?

No, chemical indicators only confirm exposure to sterilization conditions. For full validation, they should be used alongside biological indicators and process monitoring.

3. How often should chemical indicators be used in sterilization processes?

Chemical indicators should be used in every sterilization cycle and inside every sterilization pack to ensure consistent monitoring and compliance with sterilization protocols.